Pneumatics

The health of compressed air or gas systems is affected by the condition of the air supply and maintenance of the system filter and lubricator. Wet unconditioned air and oil carried from the compressor will shorten the life of sealing and moving surfaces in valves, regulators, and cylinders.

Deposits of mineral and various contaminants eventually build up and cause components to operate improperly. Leaks are so common in pneumatic systems that they become normal to the operator and it's never hard to find a lubricator that is empty or turned completely off. Contaminated and unlubricated seals and bearings eventually wear and fail.

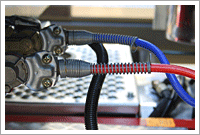

Pneumatic systems include mechanical components that require correct alignment, adaquate attachments, and well designed controls to provide long life. The same design laws that make mechanical systems solid and reliable also apply to pneumatic systems.

"We have used Machine Service Corporation since 2004 for our pneumatic, electrical and hydraulic systems troubleshooting, repairs and installations. We have experienced prompt responses to service calls, professional advice, and quality workmanship. Our shop air system was completely redesigned and installed by MSC—and when we expanded into a new facility, MSC was there to install an upgraded system as well. The facilities and manufacturing teams here at PGC rely on MSC to keep our air systems, hydraulic presses, digital cutters, shears, and punch presses up and running; and we highly recommend them!"—Dan Harvey, Precision Gasket Co.